No products in the cart.

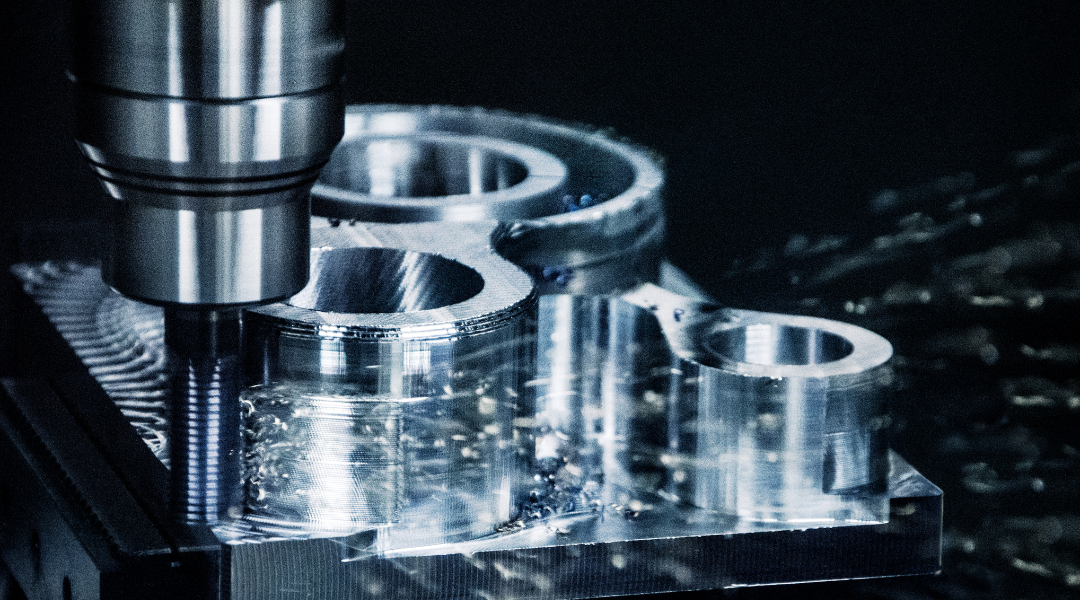

The Evolution of CNC & their Gradual Introduction to Industrial Production

CNC machines are an essential tool of modern production and their use has revolutionized its process. Their evolution and their gradual introduction into industrial production was one of the most important factors that contributed to the development of all industrial branches on a global scale, increasing the speed of the production process.

Below, we will analyze the history of CNC machines and the changes they caused in the industry.

HISTORICAL REVIEW OF CNC

The first form of CNC machines were created in the late 1940s and early 1950s. They were designed to control the movements of tools along specific paths, using punched tape as an input.

This was a technological revolution for the time, because due to the movement being controlled by machines, the production results were more precise. However, they had limited capabilities and high production costs.

In the early 1970s, the microprocessor was developed, which caused significant developments in CNC machine technology. Their programming was more flexible and easy, as with the help of the microprocessor it was possible to use a digital input.

Thus, machines with greater capabilities were created, such as multi-axis machining and the possibility of complex shapes.

THE CONTRIBUTION OF CAM & CAD SOFTWARE TO CNC USE

In the following years, technology continued to evolve and contribute to the creation of more sophisticated machines. The use of computer-aided manufacturing (CAM) software and the use of computer-aided design (CAD) software have led to the production of more complex designs, while increasing accuracy and productivity.

This resulted in a reduction in the risk of errors and defects, as manufacturers could design and simulate products before creating them.

CNC & 3D PRINTING

Another major development of CNC machines in recent years has been the introduction of 3D printing. The production of the 3D objects, from digital designs, happens thanks to the additive manufacturing technology they use. This development was very important for the production process, as it was now possible to create complex designs that were impossible to manufacture with traditional methods.

Their development also significantly affected the labor market. The automation offered by CNC machines reduced the need for manual labor in the manufacturing sectors, but increased the need for employment in other sectors.

The use of these machines requires specialized technicians and operators who have received the appropriate training in their programming and maintenance. Finally, the need increased in additional fields such as computer programming, automation engineering and robotics.

CONCLUSION

The evolution of CNC machines and their gradual introduction into industrial production has had a significant impact on the manufacturing industry. These machines help to increase the speed and accuracy of production. The evolution of CNC technology is very likely to cause more developments in the coming years.

The use of CNC machines is expected to increase as businesses are constantly looking for ways to increase efficiency and reduce their production costs.

If you need more information about CNC machines & CNC Routers, do not hesitate to contact us at 2341075889 or by e-mail at [email protected]. The experienced team of ISAC will serve you immediately by solving all your questions.