Automatic Threading Arm

ISAC Advanced Robotics is based in Kilkis and operates in the field of complex robotics in industries. The company’s Automatic Threading Arm is an essential machine to increase your productivity up to 300%. It improves your build quality due to the now standardized process and you have absolute precision in thread quality.

The frame and individual components are made of certified materials that make it suitable for industry. The machine is designed with great care and emphasis on build quality.

It is suitable for all materials such as: iron, stainless steel, bronze, aluminum, wood, industrial plastic, etc.

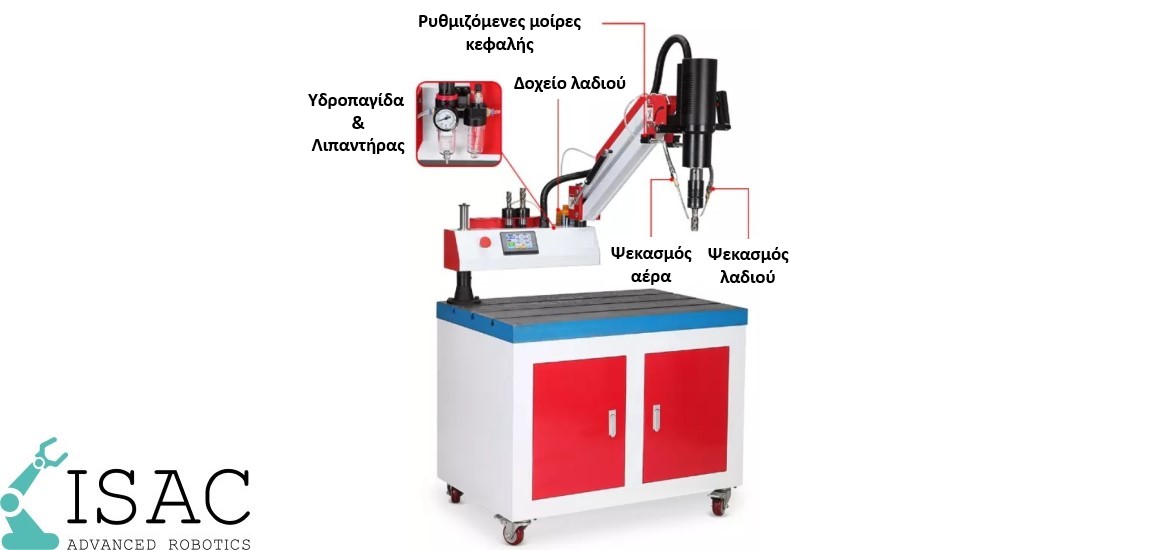

It is equipped with systems and automations to provide you with the ideal cutting conditions in every cycle. More specifically, it has:

HD Touchscreen

Touch screen (HD) with very easy operation, user-friendly, as it has English menu and quick parameter setting (thread size, pitch, hole depth, etc.)

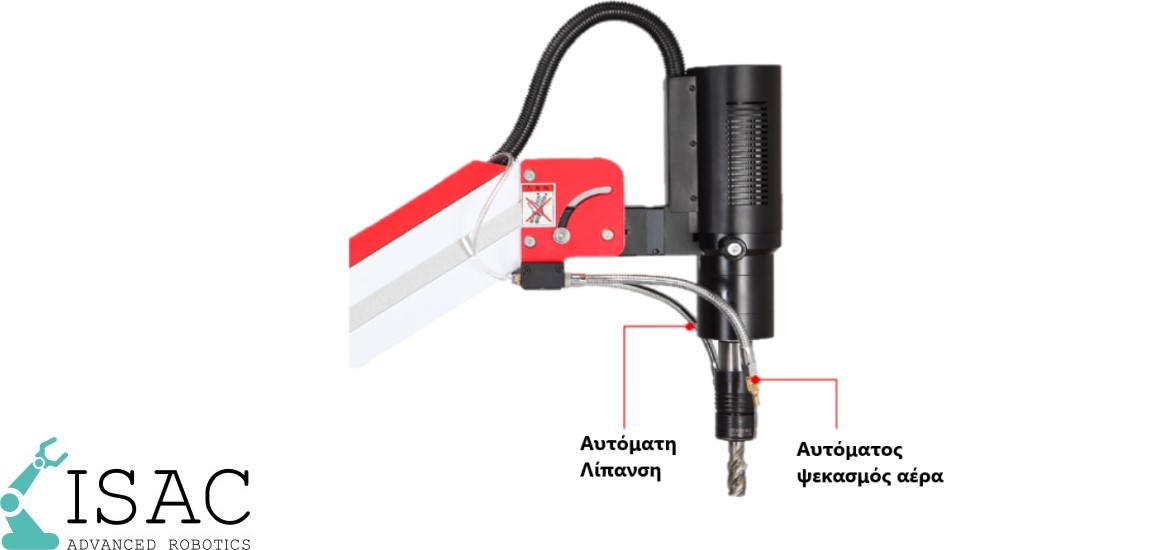

Automatic Oiling System

Automatic oil injection system (quantity adjustable) at the point of the thread to create ideal cutting conditions.

Automatic Air Blowing System

Continuous air emission system (adjustable) for optimal cleaning (from burrs) and cutter cooling.

Automatic Torque Control

Automatic torque control system for each thread, which ensures excellent results, and automatic reset in case of operator error.

Quick-Change System Chuck

Quick chuck change for any thread size in one go.

Industrial Cast Iron T-slot Table

Planed industrial T-slot table ideal for directly fixing your components or even using a vise. The table integrates into an industrial component storage bench for better management and transport.

Choose the dimensions that suit you based on your needs.

Included:

✓ 1 year warranty

✓ Training of machine operator personnel

✓ Training of program management personnel

✓ Direct technical support

Automatic Tapping Machine